Catastrophic Hip Implant Failure

Root Cause Determination

Case Summary

21st century 3D inspection technology to identify, measure, prove & illustrate the root cause of product failure

Case: Hip Implant Catastrophic Failure

-

- 57 year old male got a total hip replacement implant

- Product came apart in the body

- Metal liner detached from poly bearing

- Metal head wore:

- Through poly bearing

- Through acetabular shell

- Into pelvic bone

- Find the cause of the hip implant failure

Investigation Process

-

- 3D scan all explanted parts (accurate to 2 microns)

- 3D scan all exemplar parts (that is really accurate)

- Investigate the scan data

- Compare explanted parts to exemplar parts

- Measure the parts to CAD model & Blueprint

- We found the causes of the hip implant failure

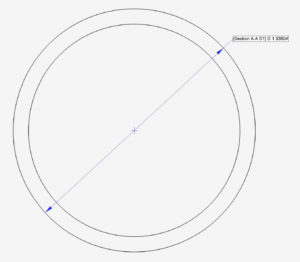

Failure Cause 1-Liner Lip Diameter

The measured size of D1 was 1.536002 inches, 0.002298 inches under nominal, 0.001298 inches under tolerance

The measured size of D1 was 1.536002 inches, 0.002298 inches under nominal, 0.001298 inches under tolerance

The undersize condition of Liner Lip Diameter coupled with an oversize condition on the poly bearing results in a bad fit assembly caused by nonconforming parts.

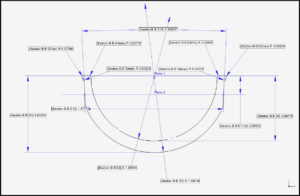

Failure Cause 2–Liner Lip Radius

The measured size of radius D2 was 0.02656 inches, 0.00656 inches over nominal, 0.00156 inches over tolerance

The size of this radius plays a key role in holding the liner in place in the assembly.

The undersized condition of several of the dimensions relate directly to the bad fit of the liner in the assembly.

Failure Cause – Non-Conforming Parts: Conclusion

The undersized condition of several of the dimensions relate directly to the fit of the liner in the assembly.

The undersized condition of several of the dimensions relate directly to the fit of the liner in the assembly.

When considered together, the out of tolerance dimensions would weaken the capture mechanism between the metal liner and the poly bearing.

Our professional opinion: these out of tolerance measurements caused or contributed to the metal liner escaping from the poly bearing, leading to failure.

How can we Help Your Cases?

- Measure any physical product to 0.000078” accuracy

- Full 3D scan with millions of data points

- Excellent Visualization supported by real engineering

- Persuasive presentation

- Professional deposition or testimony